Definition and objetives

Our current objectives are focussed in three areas:

The activities of the group relate with ceramic materials working under stringent conditions of diverse kind, such as high loads, high temperatures, corrosive atmospheres, friction and wearing conditions. These events are common in many technological systems as gas turbines and engines, spatial vehicles, fusion reactors, etc. Miniaturization of components envisaged for applications in MEMS is also a target of our research.

The group has wide expertise in the following techniques/methods: Spark plasma sintering, Thermal diffusivity/conductivity, Wear and friction tests, Fracture and strength testing, Depth sensing (micro/nano) indentation methods, Robocasting, Thermal spraying.

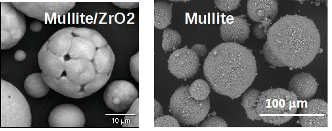

- Protective coatings for high temperature systems,

such as environmental barrier coatings (EBC) and self-healing thermal

shields. Our activities comprise: powder engineering technology, coating

deposition by flame spraying and ageing tests. Besides the main

protective function, these coatings should be able to sustain mechanical

and thermal loads without failing.

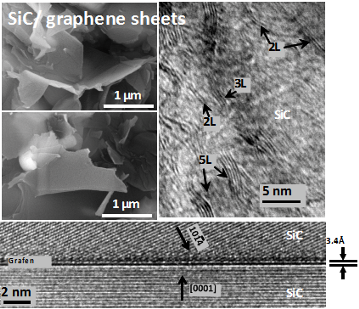

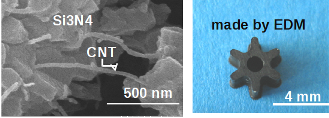

- Development of multifunctional ceramic composites containing carbon nanostructures, namely carbon nanotubes (CNT), graphene multistacks and graphene oxide (GO). Enhancement on toughness, strength or wear/friction resistance in conjunction with an added electrical conductivity or an increased thermal conductivity, induced by the carbon based nano-filler, are the aims of this research. Targeted applications are engine and turbine components, MEMS, sliding parts, etc.

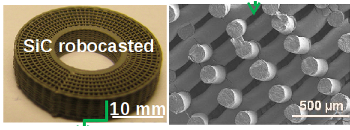

- Cellular ceramics, i.e. complex structures with high porosity and 3D assemblies using methods such as polymeric sponge replica and robocasting. A extensive range of applications, such as gas burners, catalytic supports, filters, heat sinks and exchangers, are feasible.